ผลิตภัณฑ์ทั้งหมด

-

ขดลวดอลูมิเนียม

-

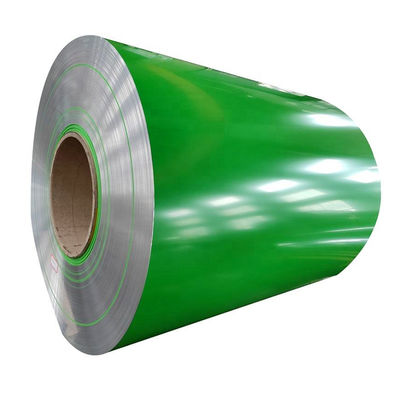

ขดลวดอลูมิเนียมเคลือบสี

-

ม้วนอลูมิเนียมฟอยล์

-

แผ่นแผ่นอลูมิเนียม

-

แผ่นวงกลมอลูมิเนียม

-

ผนังโพลีเอสเตอร์หล่อลามิเนียม

-

แผ่นอลูมิเนียมตาหมากรุก

-

แผ่นอลูมิเนียมเพชร

-

แผ่นอลูมิเนียมนูน

-

แผ่นอลูมิเนียมอโนไดซ์

-

แผ่นกระจกอลูมิเนียม

-

ภาชนะอลูมิเนียมฟอยล์

-

กล่องอาหารกลางวันอลูมิเนียมฟอยล์

-

เครื่องบาร์บีควีจ์ 1 ครั้ง

-

นกนางแอ่นครั้งแรกที่เราร่วมมือกับ Yongsheng Aluminium เราพบว่ามันง่ายมากเพราะเวลาในการจัดส่งสินค้านั้นรวดเร็วมากและผู้จัดการธุรกิจก็เป็นมืออาชีพเช่นกัน

นกนางแอ่นครั้งแรกที่เราร่วมมือกับ Yongsheng Aluminium เราพบว่ามันง่ายมากเพราะเวลาในการจัดส่งสินค้านั้นรวดเร็วมากและผู้จัดการธุรกิจก็เป็นมืออาชีพเช่นกัน -

อลิซซูบริษัท ของเราและ Yongsheng Aluminium ร่วมมือกันมาเกือบสามปีแล้ว

อลิซซูบริษัท ของเราและ Yongsheng Aluminium ร่วมมือกันมาเกือบสามปีแล้ว -

โซอี้เราซื้อวงกลมอลูมิเนียมจาก Yongsheng Aluminium และส่งไปยังประเทศกานา

โซอี้เราซื้อวงกลมอลูมิเนียมจาก Yongsheng Aluminium และส่งไปยังประเทศกานา -

อามินมาซลัมเราได้ซื้อขดลวดอลูมิเนียมสีนูนจำนวนเกือบ 500 ตันจาก Yongsheng Aluminium

อามินมาซลัมเราได้ซื้อขดลวดอลูมิเนียมสีนูนจำนวนเกือบ 500 ตันจาก Yongsheng Aluminium

ขดลวดอลูมิเนียมเคลือบ PVC ซีรีส์ 1000 & 3000 หนา 0.6 มม. ลายไม้ สำหรับรางน้ำ หลังคา ผนัง

| สถานที่กำเนิด | มณฑลเหอหนานจีน |

|---|---|

| ชื่อแบรนด์ | YONGSHENG |

| ได้รับการรับรอง | SO,RoHS,MSDS,MTC |

| หมายเลขรุ่น | 1000 3000 ซีรีส์ |

| จำนวนสั่งซื้อขั้นต่ำ | 5 ตัน |

| ราคา | 2900-3500 USD/Ton |

| รายละเอียดการบรรจุ | บรรจุภัณฑ์ที่คุ้มค่ากับทะเล |

| เวลาการส่งมอบ | 7-25 วันหลังจากการยืนยันการสั่งซื้อ |

| เงื่อนไขการชำระเงิน | l/c, d/a, d/p, t/t |

| สามารถในการผลิต | 5,000 ตันต่อเดือน |

รายละเอียดสินค้า

| อัลลอยด์ | 1050, 1060, 1100, 3003, 3004, 3105, ฯลฯ | อารมณ์ | O-H112 |

|---|---|---|---|

| ความหนา | 0.2-3 มม. | ความกว้าง | 10mm-1600mm สามารถแบ่งออกเป็นแถบ |

| ความอดทน | ± 1% | การรักษาพื้นผิว | เคลือบ PVDF, เคลือบ PE เป็นต้น |

| ความหนาของการเคลือบ | PE≥18μm, PVDF≥25μm | สี | เงิน, บรอนซ์, สีดำ, ทอง, สีน้ำเงิน, สีเทา, สดใส, ฯลฯ |

| การบรรจุหีบห่อ | ส่งออกพาเลทไม้ Seaworthy | ตัวอย่าง | ฟรี |

| เน้น | ขดลวดอลูมิเนียมเคลือบ PVC,สต็อกขดลวดอลูมิเนียมลายไม้,ขดลวดอลูมิเนียมสำหรับรางน้ำและหลังคา |

||

รายละเอียดสินค้า

1000 & 3000 ซีรีส์ PVC โคลิปอลูมิเนียมเคลือบ

0.6mm ไม้เมล็ดอะลูมิเนียมสอยสต็อคสําหรับกําแพงหลังคา gutter

ภาพรวมสินค้า

เครื่องม้วนอลูมิเนียมเคลือบ PVC รุ่น 1000 & 3000 ของเรารวมวัสดุพื้นฐานจากเหล็กสกัดอลูมิเนียมกับเคลือบที่ใช้งานเพื่อสร้างวัสดุประกอบที่หลากหลายการแปรรูปง่ายและความทนทานต่อการกัดกรองของอลูมิเนียม ด้วยความน่าทึ่งและคุณสมบัติป้องกันของเคลือบพิเศษ

การเปรียบเทียบการเคลือบ: PE vs PVDF

| ตัวชี้วัด | อลูมิเนียมเคลือบ PE | อลูมิเนียมเคลือบ PVDF |

|---|---|---|

| อายุการใช้งานภายนอก | 10-15 ปี มีแนวโน้มที่จะเสื่อมเสื่อมจากการเผชิญกับแสง UV | 25-30 ปี ทนต่อรังสี UV 98% |

| ความต้านทานต่อการกัดกรองทางเคมี | ปริมาณปริมาณปริมาณปริมาณ | อุดมสมบูรณ์ ทนทานกับฝนกรด สเปรย์เกลือ และสารปนเปื้อนอุตสาหกรรม |

| ความอดทนต่ออุณหภูมิ | -30°C ถึง 80°C อาจอ่อนและเปลี่ยนสีในอุณหภูมิสูง | -50°C ถึง 150°C ไม่แตกหรือกระจายกระจายในอุณหภูมิสูงสุด |

| ความหนาของเคลือบ | ≥ 18μm | ≥ 25μm |

| ความต้องการในการก่อสร้าง | ลายพื้น + ลายบน เหมาะสําหรับโครงการชุดเล็ก | ภายในคลุม + ผิวบนคลุม + ลานิช ต้องการโรงงานที่ไม่มีฝุ่น |

| ราคาตลาด | 32,000 - 35,000 หยวน/ตัน | 35,000 หยวน/ตันขึ้นไป |

| การใช้งานหลัก | การตกแต่งภายใน, พื้นที่อบอุ่น, โครงการภายนอกระยะสั้น | ด้านนอกของอาคารสูง โซนชายฝั่ง โซนอุตสาหกรรม |

รายละเอียดสินค้า

สายสลัดที่มีอยู่:A1050, A1060, A1070, A1100, A1235, A1245, A3003, A3004, A3105, A5052, A5083, A5754, A5005, A6061, A6082, A6063, A8011, 1235

| ซีรี่ย์สแตนเลย์ | ความหนา (mm) | ความหนาของเคลือบ | ความกว้าง (mm) | อุณหภูมิ |

|---|---|---|---|---|

| ซีรีย์ 1000 | 0.15-30 | PE≥14μm, PVDF≥25μm | 20-2200 | O,H12,H22,H14,H24,H16,H26,H18 |

| 3.0-12.0 | - | 20-2200 | H111,H112 | |

| ซีรี่ย์ 3000 | 0.2-4.0 | - | 20-2200 | O,H12,H22,H14,H24,H16,H26,H18 |

| 4.0-12.0 | - | 20-2200 | H111,H112 | |

| ซีรีย์ 5000 | 0.2-4.0 | - | 20-2200 | O,H12,H22,H14,H24,H16,H26,H18 |

| ซีรี่ย์ 6000 | 0.15-120 | - | 20-2200 | T6,T4,T651 |

ลักษณะสินค้า

- ทนต่ออุณหภูมิสูง

- ทนต่ออากาศ

- ทนต่อการขัด

- การกันเสียง

- ป้องกันกรดหรืออัลคาลี

- กันไฟ

- วัสดุน้ําหนักเบา เพื่อการก่อสร้างและการติดตั้งง่าย

ข้อมูลเพิ่มเติม

การเคลือบ:PVDF (Polyvinylidene Fluoride) PE (พอลีเอสเตอร์)

ความแข็งของเคลือบ:มากกว่า HB (ความต้านทานดินสอ)

บัตรประจําตัว:405 มิลลิเมตร 505 มิลลิเมตร

การบรรจุ:การส่งออกพัลเล็ตไม้ กล่องไม้

มาตรฐาน:ขนาดความหนา

ความแข็งของเคลือบ:มากกว่า HB (ความต้านทานดินสอ)

บัตรประจําตัว:405 มิลลิเมตร 505 มิลลิเมตร

การบรรจุ:การส่งออกพัลเล็ตไม้ กล่องไม้

มาตรฐาน:ขนาดความหนา

Yongsheng โรงงานผลิตดีเด่น

อุปกรณ์และเทคโนโลยีการผลิต

สายการผลิตเคลือบม้วนที่พัฒนามากของเราประมวลผลกลมอลูมิเนียมขนาดกว้างถึง 2350 มม.มีความสามารถในการทํางาน 24 ชั่วโมง และความสามารถในการแปรรูปรายวันละ 400-500 ตัน, เรารับประกันคุณภาพที่คงที่ ผ่านกระบวนการเคลือบและแปรงที่แม่นยํา

การเลือกวัสดุที่มีคุณภาพ

เราใช้อะลูมิเนียมพรีเมียมจากผู้ผลิตชั้นนํา รวมถึงอะลูมิเนียมตะวันตกเฉียงใต้, นานชานอะลูมิเนียม, และอะลูมิเนียมจีนวัสดุการเคลือบของเรามีแบรนด์ชั้นนํา เช่น PPG อเมริกันและเบคเกอร์สวีเดน, รับประกันความทนทานต่ออากาศและการป้องกันการกัดกร่อนที่ดีกว่า

ระบบควบคุมคุณภาพ

การควบคุมคุณภาพที่ครบถ้วนของเรารวมถึงหลายระยะการตรวจสอบ จากวัสดุแท้ถึงผลิตภัณฑ์ที่เสร็จสิ้น เราทําการทดสอบการกวาดสําหรับการติดต่อเคลือบ,การรับรอง ISO9001 และ ISO14000 ของเรา รวมไปถึงการปรับปรุงกระบวนการโดยใช้ข้อมูล

บริการปรับแต่ง

เรานําเสนอรายละเอียดที่หลากหลายรวมถึงความหนาจาก 0.018-1.5 มิลลิเมตรและความกว้างจาก 50-1600 มิลลิเมตรปลายที่ทนต่อรอยขีดข่วน, และรูปแบบสีที่ส่องสว่าง เพื่อตอบสนองความต้องการการใช้งานเฉพาะของคุณ

ภาพสินค้า

การใช้งานสินค้า

แนะนำผลิตภัณฑ์